ai assistant for construction: why ai in construction matters for the construction industry and construction materials suppliers

The construction sector faces tight margins and fast changes. Suppliers see fluctuating demand, complex logistics, slow manual takeoffs and fragmented communications every day. These issues increase rework and raise costs. For this reason, many companies evaluate AI as a way to automate routine tasks and improve throughput. An AI assistant for construction can answer product questions, surface real-time stock, and route requests to the right team. When used well, it helps reduce manual triage and improve response quality.

Fact: McKinsey estimates generative AI could add 0.5–3.4 percentage points of annual productivity growth across sectors. This boost is relevant to supply chains and suppliers that strive to cut lead times and avoid shortages. However, the construction industry often lacks large, clean datasets. As researchers note, “limited access to large datasets is a major obstacle for implementing deep learning models” in construction; nonetheless, rule-based and hybrid AI approaches still deliver value (MDPI).

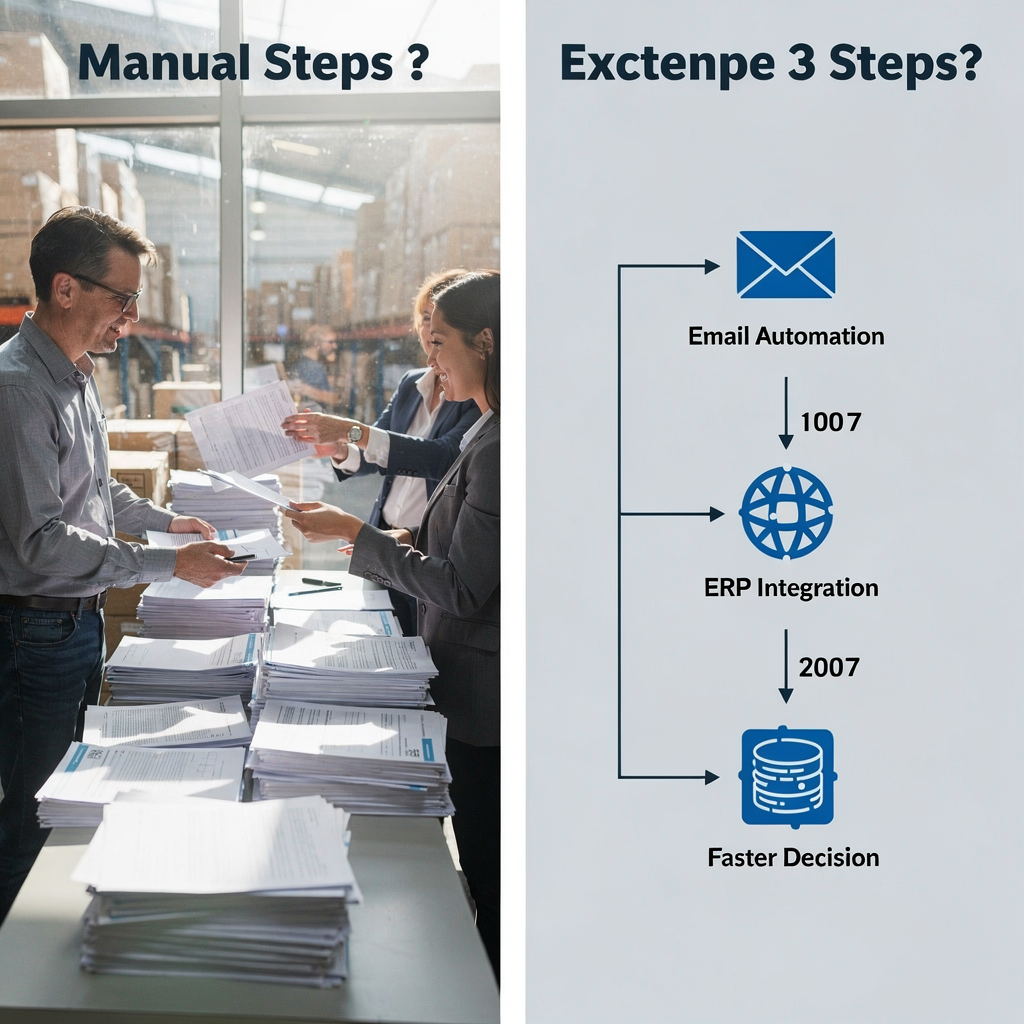

To be clear, AI does not replace human expertise. Instead, it complements it. For example, an AI assistant can triage emails, summarize RFIs and link them to project documents. Then, a human estimator or project manager reviews the work and signs off. This hybrid model reduces errors and speeds up approvals. Also, construction professionals gain time to focus on complex issues. For operations teams that face high email volumes, products like virtualworkforce.ai use AI agents to automate the full email lifecycle. This approach reduces handling time, increases consistency, and keeps context across long conversations.

Before and after process maps make the impact obvious. A manual process shows many handoffs and waiting times. By contrast, an AI-powered process reduces steps and shortens cycle times. For suppliers, that means faster quotes, fewer stockouts, and better service to contractor customers. Finally, integrating with platforms such as Procore and ERP systems lets teams maintain a single source of truth and deliver seamless workflows across sales and operations.

use ai to streamline takeoff and estimate with ai tools and estimator automation

Estimating remains a bottleneck for suppliers who support construction projects. Manual takeoff from construction plans and PDF drawings takes hours per sheet. By contrast, AI-powered takeoff accelerates the task. Computer vision reads drawings and BIM files. Then, estimator logic and supplier price feeds convert quantities to costs. The result is faster, repeatable estimates with fewer errors. Case studies report automated takeoffs can cut time per sheet dramatically and save roughly 90 minutes per sheet in practical settings. Those figures highlight measurable gains and better use of estimator time.

Use AI to automate repetitive calculations. First, the system extracts areas, lengths and counts from drawings. Next, it normalizes the data to SKU mappings. Then, it applies pricing rules and discount logic. This workflow reduces variance between bids. It also helps construction companies and construction firms submit accurate quotes faster. In one workflow, a takeoff-specialist tool reads the plan, flags unclear areas for human review, and pushes a draft estimate into the ERP. The estimator reviews the draft. Finally, the supplier issues a firm quote to the contractor.

AI tools vary in scope. Some focus on pure takeoff and integrate with BIM. Others include estimator platforms that manage labor and waste factors. Integrated suites tie takeoff to procurement lists and inventory. For example, computer vision combined with building information modeling produces precise quantities. Then, price feeds and analytics adjust for current market rates. That combination can improve cost accuracy by up to around 20% in early implementations.

For teams starting out, a short sample workflow helps. First, ingest construction documents into the ai software. Second, run a takeoff pass and map results to SKUs. Third, attach supplier prices and apply margin rules. Fourth, present the estimate to the estimator for review. Also, keep a versioned audit trail so the estimator can see what changed. Finally, measure time saved and estimate accuracy versus historical baselines. If you want a practical primer on automating logistics correspondence and email-driven workflows that link to takeoff outputs, see resources on automated logistics correspondence.

Drowning in emails? Here’s your way out

Save hours every day as AI Agents draft emails directly in Outlook or Gmail, giving your team more time to focus on high-value work.

integrating ai into workflow, erp and management software for real-time inventory and seamless procurement

An AI assistant must connect to ERP, CRM and construction software to deliver value. Only then can it show real-time inventory, lead times and accurate pricing. For a supplier, that visibility reduces stock holding and minimizes shortages. When systems align, AI can trigger seamless reordering and improve fulfillment. This reduces the number of emergency orders that disrupt production and delivery schedules.

Integration commonly uses APIs or middleware. This approach keeps existing management software in place while enabling new ai solutions to access project data and transactional records. However, integration requires careful mapping of SKUs, units and supplier lead times. Poor data hygiene creates twin problems: wrong recommendations and lost trust. Therefore teams should audit data sources, standardize SKUs, and establish governance before deployment. For a tactical guide to connecting email to ERP workflows and cutting manual lookups, review how ERP email automation ties systems together.

Benefits of this integration are clear. Suppliers can automate reorder points, and the system can suggest alternate sources when lead times extend. Real-time tracking improves accuracy and reduces waste. Predictive alerts identify bottleneck items before they cause delays. Also, AI-powered analytics surface reorder opportunities based on seasonality and project schedules. This reduces obsolete inventory and helps with resource allocation across jobs.

Here is a quick checklist for IT teams and operations leads: identify core data sources, confirm API availability, map SKUs and units, define user roles and access, and test security controls. Then pilot with one product line and one warehouse. Use short iterations and validate stock accuracy against physical counts. Finally, document integration points and update training for project managers and construction teams. For teams exploring scaling operations without hiring, see guidance on how to scale logistics operations with AI agents at our resource on scaling logistics operations.

ai agents and ai assistant automation for procurement, submittals and construction communications

AI agents change how teams handle procurement and submittals. They act as always-on delegates that process supplier queries, generate purchase orders, and manage submittal packages. For example, an ai agent reads an incoming email, extracts the request, verifies stock and then drafts a PO. It can also attach relevant project documents and push the transaction into the ERP. That flow reduces manual errors and speeds approvals.

These agents also handle construction communications. They respond to common questions about pricing and availability and route complex issues to humans. As a result, response times fall and consistency improves. Suppliers get fewer phone escalations. Site teams get timely answers for materials delivered to the construction site. For operations teams overwhelmed by email, automating routine tasks with AI agents reduces triage and increases throughput. virtualworkforce.ai focuses on automating the full email lifecycle. The platform uses AI agents to label intent, ground replies in TMS or WMS data, and escalate only when needed.

Operational gains are measurable. Teams often see faster approvals, fewer errors in submittals, and shorter cycle times for RFIs and RFQs. Suggested KPIs include response time, order accuracy, submittal turnaround, and percentage of interactions automated. Track these over time to show ROI. Moreover, conversational AI can assist with vendor negotiation by surfacing pricing trends and historical terms. At the same time, maintain governance and audit trails so every action remains traceable and compliant.

Practical deployment tips: start with a narrow use case such as order confirmations or common supplier questions. Then expand to submittal routing and submittals management. Provide clear escalation rules and update the knowledge base frequently. Also, test integration with existing tools like Procore to ensure the submittal documents and project schedules align. This staged approach minimizes disruption and builds trust with both internal teams and external vendors.

Drowning in emails? Here’s your way out

Save hours every day as AI Agents draft emails directly in Outlook or Gmail, giving your team more time to focus on high-value work.

data-driven project management and ai-driven insights to help contractors and construction firms make informed decisions

AI turns project data into actionable insights. Suppliers and contractors benefit from predictive analytics that forecast demand, flag lead-time risk, and model cost swings. This capability reduces change orders and improves margins. For instance, early alerts about material shortages allow procurement teams to secure substitutes or expedite shipments. Then projects can stay delivered on time more often.

Use predictive models to plan inventory across multiple jobs. Start by aggregating data from ERP, project documents and purchase history. Next, run a pilot for one product line and compare forecast accuracy against a baseline. Many teams achieve meaningful reductions in stockouts and waste when they use predictive analytics. Research in operations and supply chain shows real-world improvements in uptime and scrap reduction that apply to material handling as well (NIST).

AI-driven dashboards give project managers and construction professionals a consolidated view of risk and opportunity. For example, a dashboard might show items with rising lead times, orders at risk of delay, and suggested alternative suppliers. That information helps contractors and suppliers make informed decisions about sourcing, scheduling, and contingency buying. Also, data-driven insights enhance quality and safety by predicting where shortages could force schedule compression and increase onsite accidents.

To begin, assemble cross-functional teams that include procurement, sales and a project manager. Then define the metrics that matter: forecast accuracy, stockouts, lead-time variance and margin impact. Run short sprints, measure improvements, and refine models. Finally, keep humans in the loop. AI models improve with feedback. As data quality improves and models mature, these solutions will play a larger role in transforming the construction industry and modern construction practices.

challenges in construction and steps to integrate ai software that will revolutionize and transform the construction industry

Challenges in construction are real. Key barriers include data scarcity and quality, integration cost, staff training, and trust in automated recommendations. Data from various sources often sits in silos. That fragmentation makes it hard to train accurate ai models. Also, integrating new AI software with legacy ERPs and CRMs adds complexity and expense. For these reasons, suppliers should follow a pragmatic approach when rolling out AI solutions.

Start with a practical roadmap. Prioritize high-ROI workflows such as takeoff, procurement and inventory. Run short pilots that focus on a single product line or warehouse. Clean the relevant data and map SKUs carefully. Next, integrate using API or middleware and validate each step with users. Train staff and document governance. This staged approach lowers risk and builds confidence. For teams that want to scale without hiring, consider leveraging AI agents to handle volume and reduce manual triage across sales and operations.

Trust matters. Suppliers need explainability, audit trails and consistent performance to embrace AI. Use models and rules that provide clear reasoning. Also, choose solutions that require minimal prompt engineering and that embed governance into the setup. At virtualworkforce.ai we emphasize thread-aware memory and deep data grounding so teams see the source of every recommendation. That design reduces the bottleneck of manual email triage.

Looking ahead, as data availability improves and ai models advance, AI construction and cutting-edge AI tools will increasingly revolutionize workflows. Over time, these systems will link procurement, planning and execution across the construction cloud. To move forward today, audit your data readiness, pick one pilot use case, measure ROI and plan integration with existing construction management software. Doing so will help you embrace AI-driven automation while protecting operations and improving project outcomes.

FAQ

What is an AI assistant for construction and how does it help suppliers?

An AI assistant for construction is a software agent that automates routine tasks like answering inquiries, extracting data from project documents and drafting purchase orders. It helps suppliers respond faster, reduce manual errors and maintain better inventory control.

How can I use AI to streamline takeoff and estimating?

Use computer vision and building information modeling to extract quantities from plans. Then connect those quantities to price feeds and estimator logic. This process speeds up takeoff, improves cost accuracy and makes estimates repeatable.

Will AI integrate with my ERP and Procore?

Yes. Most AI solutions connect via APIs or middleware to ERP, CRM and platforms like Procore to provide a single source of truth. Integration requires SKU mapping, data hygiene and security checks, but the result is seamless procurement and real-time stock visibility.

What are common use cases for ai agents in procurement?

AI agents can handle supplier queries, generate purchase orders, manage submittals and route RFIs. They automate repetitive email work, draft accurate replies, and escalate only when human input is required.

How do I measure the impact of AI on my operations?

Track KPIs such as response time, order accuracy, submittal turnaround and percentage of automated interactions. Also measure forecast accuracy, stockouts and time saved on takeoffs to calculate ROI.

What about data quality and model accuracy?

Data quality is essential. Clean, standardized SKUs and consistent units improve model accuracy. Start small, validate results, and iterate to reduce errors and build trust with users.

Can AI reduce rework and improve safety?

Yes. By improving planning and predicting shortages, AI lowers the chances of rushed changes that cause rework. Better scheduling and supply reliability also reduce safety risks on site.

Is it possible to automate the full email lifecycle for operations?

Yes. Solutions like virtualworkforce.ai automate the lifecycle by labeling intent, grounding replies in ERP/TMS/WMS data and drafting replies. That reduces time spent on triage and increases consistency.

How should suppliers start an AI pilot?

Choose a high-impact, low-complexity workflow such as takeoff or order confirmations. Clean the data, integrate with ERP for one product line, run the pilot, and measure improvements before scaling.

What should I expect from the future of AI in construction?

AI-driven insights will grow more accurate as data improves. Over time, these tools will help suppliers optimize procurement, improve forecasting and support better decision-making. The outcome will be improved margins and more reliable project delivery.

Ready to revolutionize your workplace?

Achieve more with your existing team with Virtual Workforce.