ai agent for procurement in aerospace: how ai-driven agents transform supplier workflow

AI agent software is changing how procurement teams in the aerospace sector work. An ai agent acts as an autonomous assistant that can read inputs, consult a dataset, and then act. It helps procurement with demand planning, spend analysis, and predicting part failures so teams can make informed decisions fast. For example, predictive maintenance signals can feed procurement to prioritise spare parts and reduce lead times. Studies show predictive maintenance with AI can cut unplanned downtime by roughly 15–25% (case studies). This makes procurement more proactive and less reactive.

Common ai-driven use cases include demand forecasting, supplier consolidation, and automated purchase order creation. They also include automated invoice matching and supplier performance alerts. When suppliers report delays, an agent can analyse vast telematics and delivery data and then recommend actions. This provides real-time visibility and helps procurement teams avoid late deliveries.

Adoption is rising across aerospace companies. Surveys find about 60%+ of firms use AI in some capacity (industry survey). Pilots often report production efficiency gains of 30–40% in automation pilots (industry report). Those improvements help suppliers reduce manual effort and lower costs through smarter inventory and faster cycle times.

At virtualworkforce.ai we focus on the largest unstructured workflow: email. Our AI agents automatically read supplier messages, extract contract and delivery facts, and then draft or route replies. This reduces handling time dramatically and lets procurement staff focus on supplier negotiations and relationship work. In short, agentic AI helps procurement streamline routine tasks, while human experts handle complex judgement calls.

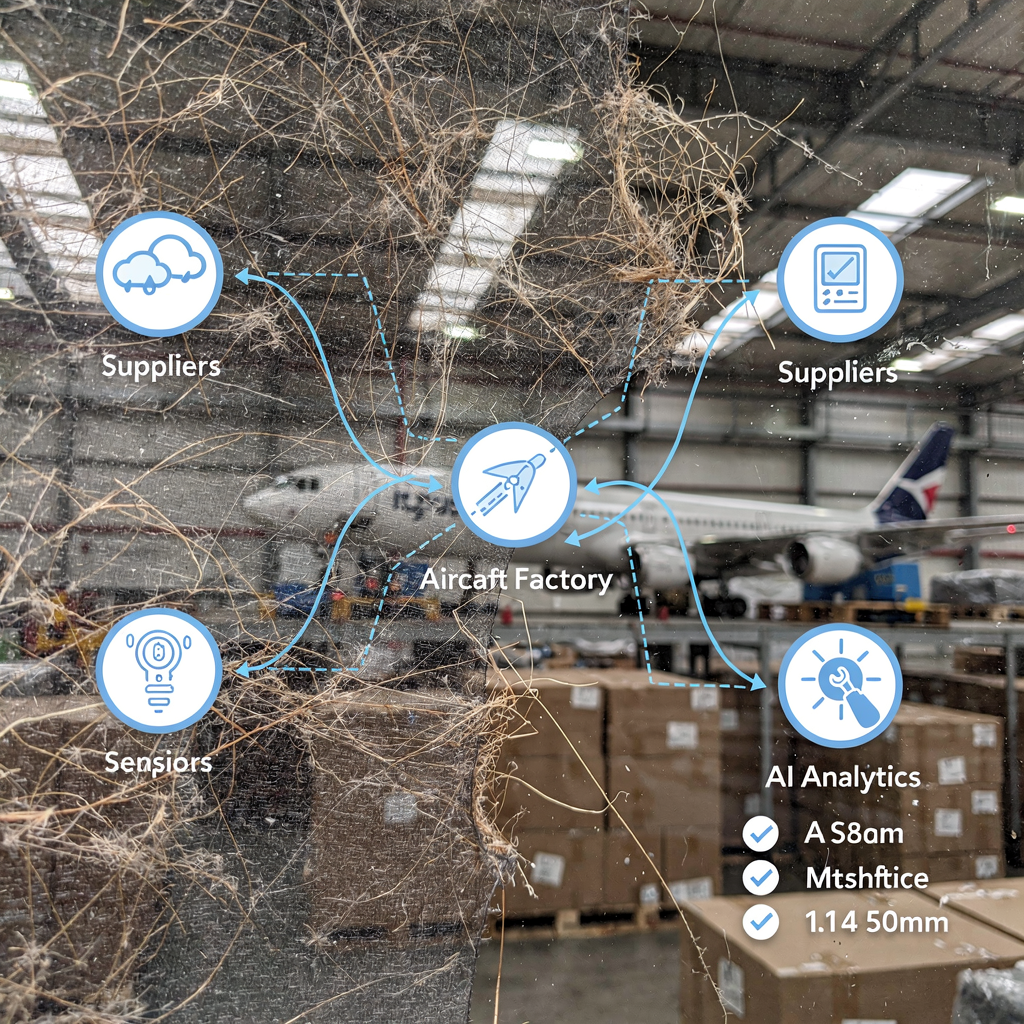

automate and automation: intelligent automations to integrate with erp and multiple systems

Clear architecture separates automation from intelligent automations. Automation covers scripted work. Intelligent automations add learning, orchestration, and natural language understanding. They sit above legacy systems and orchestrate data across erp systems, TMS, WMS and document stores. To integrate, teams use APIs, event buses and data harmonisation layers so agents can query a single source of truth. Clean master data makes this easier.

Integrate with existing ERPs to reduce exceptions. Automation can match POs to invoices automatically. When mismatches occur, an ai agent can draft a query and attach relevant records. That lowers manual effort and speeds PO-to-pay cycles. Case studies show that intelligent automations improve invoice accuracy and reduce manual touches substantially. For ERP email use cases, see our guide to erp email automation for logistics for concrete examples (ERP email automation).

Architectural patterns include a canonical dataset that normalises supplier identifiers, item masters, and routing rules. Agents then call predictive analytics models to forecast demand and to flag real-time risk. The integration of ai often starts with a pilot focused on high-volume workflows and is then expanded. KPI suggestions include reduced manual touches, faster PO-to-pay cycle, and lower error rates.

When erp and AI integrate, organisations unlock benefits across cost, speed and compliance. Intelligent automations help teams automate repetitive email replies, route queries correctly, and keep supplier documentation attached. That creates a seamless data flow and reduces rework. For practical steps to setup zero-code email agents for operations see our virtual assistant logistics page (virtual assistant logistics).

Drowning in emails?

Here’s your way out

Save hours every day as AI Agents label and draft emails directly in Outlook or Gmail, giving your team more time to focus on high-value work.

source and supplier risk assessment with ai-powered models to remove bottleneck

Supplier risk assessment is a natural fit for ai-powered models. Models ingest financial filings, delivery history, shipment telemetry, and geo-political indicators to score suppliers. This enables earlier detection of distress and reduces single-source bottleneck risk. For example, combining delivery delays with cash-flow signals gives procurement an early warning. Alerts can trigger re-sourcing or safety stock decisions. That lowers the chance of production stoppage in aerospace manufacturing.

Typical risk signals include financial ratios, on-time delivery trends, quality incidents, and regional disruption indices. Machine learning models analyse historical patterns and external feeds to predict supplier failure probability. These systems can provide real-time risk alerts so teams can act before a shortage impacts production. The integration of ai agents in aerospace helps link those alerts to procurement actions.

Outcome metrics include fewer late deliveries, quicker re-sourcing cycles, and reduced single-source exposure. In practice, an agent monitors hundreds of suppliers, surfaces a risk score, and attaches supplier documentation for quick review. Then the procurement team decides whether to accelerate orders or approve a second source. This approach helps manage supplier relationships and keeps compliance traceable.

Experts note the strategic nature of these tools. As one industry voice put it, “The integration of AI agents in aerospace supply chains is not just a technological upgrade but a strategic imperative” (IATA-related report). That perspective underlines why investing in ai to manage supplier risk assessment is now a priority for the aerospace sector.

procurement team in the aerospace industry: agentic assistants that deliver a competitive edge

Agentic AI redefines what a procurement team does. Agents take over routine tasks like PO creation, invoice triage, and basic negotiations. Humans retain strategic sourcing, complex negotiations, and supplier development work. This blend gives teams a competitive edge because it speeds decisions while preserving human judgement.

An agentic assistant can monitor supplier performance and surface anomalies. It can also draft contractual language and check compliance against standards. Using AI platforms that ground replies in engineering data helps keep messages accurate. For unstructured inputs such as vendor emails, natural language agents extract intent and attach evidence. virtualworkforce.ai uses this pattern to reduce manual email handling and to provide actionable context to humans.

Teams benefit from faster cycle times and more consistent compliance. Agents can forecast shortfalls, propose alternate suppliers, and even start approval workflows. These capabilities help procurement focus on strategic categories and supplier development, rather than repetitive tasks. The impact of ai in these workflows includes lower costs, fewer errors, and better supplier performance overall.

Change management matters. Teams must train staff on agent needs, governance and escalation. Clear rules and audit trails keep the system trustworthy. As agentic systems continue to evolve, procurement professionals will need new skills in oversight, model validation, and vendor management. That is the future of procurement in the aerospace industry.

Drowning in emails?

Here’s your way out

Save hours every day as AI Agents label and draft emails directly in Outlook or Gmail, giving your team more time to focus on high-value work.

supply chain and aerospace workflows: ai agent use cases that revolutionize and automate procurement end‑to‑end

Map a typical aerospace workflow from demand signal to delivery and you will see many points where an ai agent can add value. Predictive analytics turn machine telemetry into spare parts forecasts. Agents then automate sourcing, raise POs, and check approvals. This reduces stockouts and keeps assembly lines moving. Industry reports show production efficiency gains of 30–40% in automation pilots (efficiency gains).

Use cases include predictive maintenance triggering automated spare parts orders; dynamic re-routing of orders when risks surface; and automated quality-audit scheduling. Agents can also manage supplier documentation and compliance checks, keeping traceability for regulatory audits. These capabilities help meet the evolving needs of aerospace regulators and customers.

AI agents provide real-time tracking and real-time risk signals. They can analyse vast telemetry and supplier data to provide early warnings and to recommend sourcing alternatives. This lets teams make informed decisions and reduce costs from emergency orders. For aerospace manufacturers, automating workflows without extensive replatforming is crucial. Lightweight integrations let agents orchestrate across multiple systems and deliver results quickly.

Finally, keep a focus on metrics. Track downtime avoided, reduction in urgent buys, and percentage of decisions automated. Together, these show the value of agentic systems and help justify further investment in ai tools and ai platforms. As aerospace workflows adopt these systems, the world of aerospace will see faster, safer and more resilient operations.

best practices to source and integrate ai-powered solutions: measuring impact and planning the future of procurement

Start with clean supplier data and clear KPIs. That forms the basis for successful integration of ai agents. Run a small pilot, measure supplier lead time variance, cost to procure, and downtime avoided. Use those metrics to build a business case for scaling. The market for AI in supply chain is growing rapidly, and aerospace companies that delay risk falling behind.

Secure architecture and data governance are essential. Address cybersecurity, model explainability, and audit trails up front. Integrate with existing ERPs through APIs and canonical datasets so agents can query a single source of truth. Build in role-based access and logging so every decision is traceable. When deploying, use phased rollout to manage change and to keep manual effort low.

Best practices include piloting on high-impact workflows, training staff on agentic governance, and using continuous monitoring to detect model drift. Track % of automated decisions, ROI timelines, and supplier documentation accuracy. Plan for continuous learning so agents continue to improve with new data and evolving agent needs. For guidance on scaling operations with AI agents, see our how-to guide on scaling logistics operations with AI agents (scaling guide).

Finally, remember that investing in ai is not only technical. It is organisational. Build cross-functional teams, include procurement, IT and engineering capabilities, and focus on strategic outcomes. Doing so will unlock the full potential of AI and help shape the future of aerospace procurement.

FAQ

What is an AI agent in procurement?

An AI agent is an autonomous software assistant that performs tasks such as triaging supplier emails, matching invoices, and suggesting suppliers. It acts on data, applies rules and models, and escalates complex items to humans with full context.

How do AI agents help reduce unplanned downtime?

They turn machine telemetry into predictive analytics and then trigger sourcing actions, such as ordering spares early. Studies report predictive maintenance can reduce unplanned downtime by roughly 15–25% (case studies).

Can AI integrate with legacy ERP systems?

Yes. Agents typically integrate via APIs or an event bus and use a canonical dataset for harmonised identifiers. That approach lets organisations keep legacy erp systems while adding intelligent automations.

Are AI agents secure and auditable?

When deployed with role-based access, logging and governance, agents are auditable. Teams should include security reviews and model explainability in pilots to ensure compliance and traceability.

How do AI agents support supplier risk assessment?

Agents ingest delivery history, financial signals and external indicators to score suppliers and flag potential distress. Early alerts give procurement time to re-source or to increase safety stock before shortages occur.

Will AI replace procurement staff?

No. Agents handle repetitive tasks and provide actionable context. Humans remain essential for strategy, negotiation and supplier development. This collaboration improves speed and quality of decisions.

What KPIs should I track for AI pilots?

Track supplier lead time variance, % of automated decisions, downtime avoided, cost to procure, and ROI timelines. These quantify the operational and financial impact of pilots.

How quickly can aerospace suppliers deploy agents?

Many pilots deploy in weeks when data and access are prepared. Focus first on high-volume, high-friction workflows to show early wins and to build momentum.

Do AI agents help with regulatory compliance?

Yes. Agents can attach supplier documentation, log decisions, and ensure traceability for audits. They help maintain records required by regulators.

Where can I learn more about operational email automation?

For specific examples of automating logistics and operations email, see our resources on virtual assistant logistics and erp email automation, which explain workflows and ROI in detail (virtual assistant logistics, ERP email automation).

Drowning in emails?

Here’s your way out

Save hours every day as AI Agents label and draft emails directly in Outlook or Gmail, giving your team more time to focus on high-value work.