ai agent and agents in oil and gas — what agentic systems are and why they matter

An AI agent is software that senses, decides and acts on operational data with limited human input. In plain terms, one AI agent can read sensor streams, query databases, make a decision and then execute an action or suggest a human action. Agentic AI refers to systems that operate with purpose and autonomy across a task set. These agentic systems matter in oil and gas because they help teams move from reactive to proactive workflows across operations.

Across exploration, production, safety and logistics, agents in oil and gas perform repeating tasks, handle exceptions and surface high‑value alerts to engineers. For example, an agentic AI agent can monitor pressure trends on a production well, decide whether to reduce throughput, and then automatically schedule a technician if thresholds persist. This blend of autonomous decision-making and human oversight helps reduce risk and improve operational efficiency.

AI agents augment human decision‑making and enable autonomous systems for routine and urgent tasks. They support decision quality by combining massive amounts of data with domain rules and statistical models. At the same time, they create clear audit trails for regulators and investors. Importantly, companies using these agents often pair them with dashboards and enterprise AI governance so that humans retain control where safety matters most.

In operations where email and messaging drive much of the daily coordination, AI agents also automate communications. For instance, virtualworkforce.ai builds AI agents that automate the full email lifecycle for ops teams, reducing manual work in shared inboxes and improving response consistency. This helps streamline handoffs between field crews and back‑office teams while preserving traceability.

Finally, agentic approaches let oil and gas companies test autonomous agents in low‑risk workflows, then scale them into core processes. This staged ai journey reduces disruption and accelerates adoption while ensuring safety and compliance remain central. As a result, oil and gas operations can reshape how they plan, execute and report work.

upstream oil and gas, seismic data and drill optimisation — ai-driven exploration gains

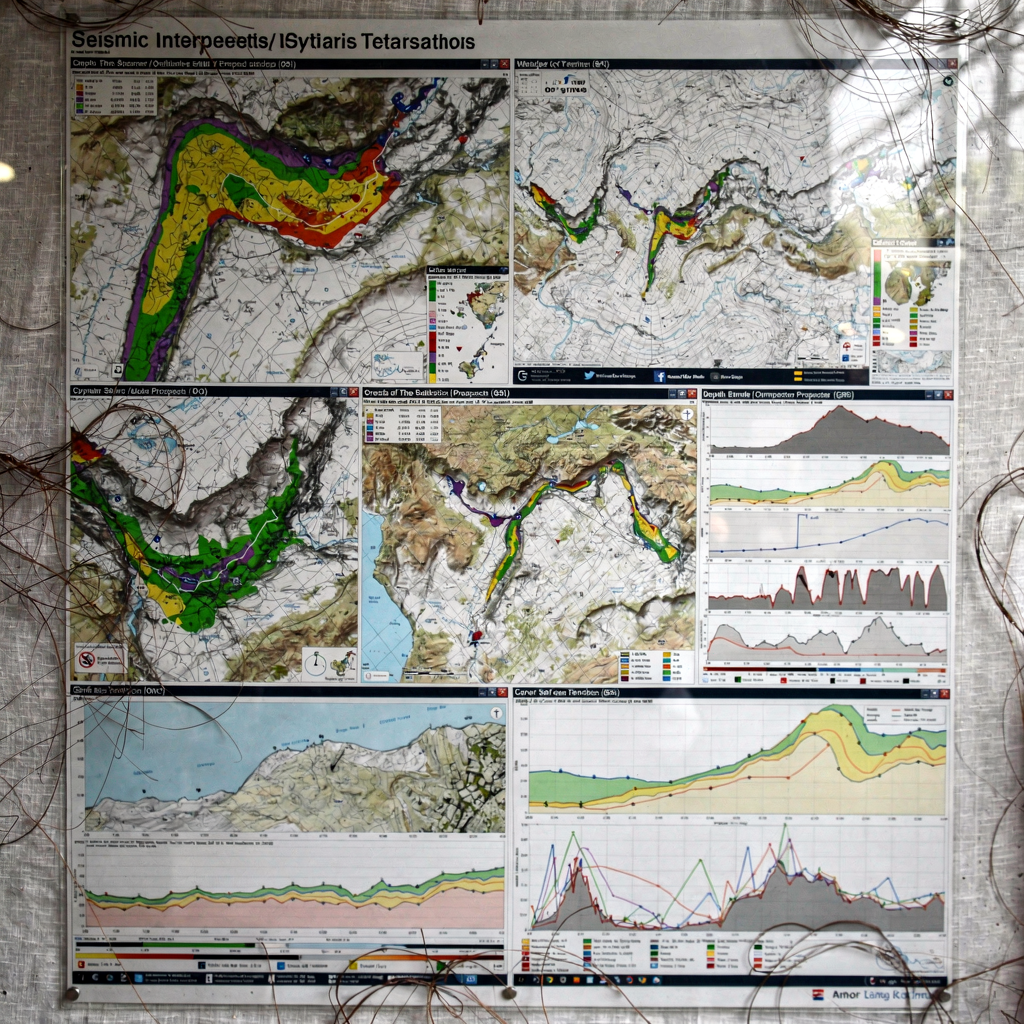

AI-driven models have transformed how teams evaluate seismic data and rank prospects. By combining seismic, well logs and geological models, these AI models find subtle patterns that human interpreters might miss. Consequently, teams can identify promising drilling targets faster and with higher confidence. For example, BP reports an approximate 30% improvement in exploration accuracy after deploying AI models for subsurface analysis, which directly lowers dry‑hole risk and saves capital BP: exploration accuracy ~30%.

Seismic data and well logs produce massive amounts of data. Therefore, ai models use supervised learning, unsupervised clustering and physics‑informed networks to sift signals from noise. As a result, exploration teams can rank prospects and forecast drilling outcomes with refined probability scores. In turn, that reduces exploration capex risk and speeds project cycles.

AI agents can autonomously ingest seismic data, run prebuilt models, and produce a ranked list for geoscientists to review. Then, geoscientists validate suggestions and adjust drilling plans based on operational context. This collaborative loop helps companies shift from hypothesis‑driven exploration to data‑driven selection.

Beyond prospect ranking, these systems aid in identify promising drilling sequences that reduce sidetrack needs and shorten rig time. This saves time and money and reduces wells that fail to meet target performance. Firms that adopt these practices reduce inefficiency in the field, accelerate decision cycles and often gain a competitive edge in acreage appraisal.

For teams early in their ai journey, start with pilot projects on well understood fields. Use an ai platform that integrates with existing data stores and geoscience tools so that geologists and drilling engineers can co‑develop models. This approach helps scale AI while managing technical risk and change management across upstream oil and gas.

Drowning in emails?

Here’s your way out

Save hours every day as AI Agents label and draft emails directly in Outlook or Gmail, giving your team more time to focus on high-value work.

predictive maintenance, predictive and operational efficiency through automation

Predictive maintenance agents monitor asset health and forecast failures using sensor analytics, historical maintenance records and domain heuristics. These agents combine IoT streams with physics‑based rules and ai models to forecast issues before they interrupt production. Consequently, teams can schedule maintenance during planned windows instead of reacting to failures. Industry studies and case examples show maintenance cost reductions of approximately 15–20% and fewer unscheduled outages research: maintenance cost reductions ~15–20%.

Predictive maintenance reduces downtime and increases asset life. For example, vibration and temperature trends on pumps and compressors often precede mechanical failure. Predictive agents detect anomalous patterns and flag them with a probability score. Then, ops teams or automated work order systems act to prevent failure. When integrated with workforce scheduling and parts inventory, these agents can also automate ordering and technician dispatch.

Automation here improves uptime and cuts operational costs. A predictive agent that forecasts failure can coordinate a maintenance window, pull parts from inventory, and place a maintenance ticket. This orchestration reduces handoffs and miscommunication across operations. As a result, the plant spends less time offline and enjoys better production consistency.

To get performance, companies should combine sensors, domain models and a dashboard that displays risk levels and recommended actions. That dashboard helps engineers prioritize work and ensures that safety and compliance steps are visible. Moreover, tying predictive maintenance into broader workflow orchestration lets organizations scale automated responses while retaining manual overrides for complex cases.

Finally, predictive maintenance forms a foundation for operational excellence. It helps transform oil and gas operations from reactive to proactive and reduces operational and financial pain points. By focusing pilots on high‑value assets and measurable KPIs, teams can prove ROI and then expand the approach across fleets.

workflow orchestration to streamline workflows across the plant — ai platform and orchestrate

An ai platform with an orchestration layer helps streamline tasks across teams and assets. It connects models, data sources and business rules so agents can orchestrate multi‑step processes. For example, an orchestration layer can take an alert from a pump monitor, check spare parts availability, route a technician, and then update production schedules. That single coordinated flow reduces manual handoffs and speeds decision loops.

Workflow automation helps remote operations and enterprise roll‑outs. Remote ops teams often depend on emails, chats and phone calls to coordinate field interventions. An ai platform can ingest inbound messages, extract intent and attach context from ERP or equipment histories. For operations teams that suffer high email volumes, virtualworkforce.ai automates the full email lifecycle for ops teams so that shared inboxes no longer block progress and context is preserved across threads. See practical guidance on automating logistics emails for similar patterns automate logistics emails.

Orchestration delivers clearer audit trails, faster response times and easier integration with legacy systems. It also supports enterprise AI governance: permissioning, logging and human escalation points ensure safety. Use cases include automated alerts, schedule optimisation, remote work execution and enterprise rollout of AI solutions. A strong orchestration approach helps companies scale by making each agent part of a managed, observable system.

To scale safely, start with a small set of automated workflows that have clearly measurable outcomes. Next, connect the workflows to a centralized ai platform that provides model management, version control and data lineage. Finally, ensure that operations teams can configure routing rules and escalation paths without writing code. This approach reduces change friction and lets business users shape the workflows that run across operations.

Drowning in emails?

Here’s your way out

Save hours every day as AI Agents label and draft emails directly in Outlook or Gmail, giving your team more time to focus on high-value work.

environmental monitoring and esg with genai, ai technology and forecast optimisation

Agents for environmental monitoring detect leaks, measure emissions and forecast environmental outcomes using sensor networks and multimodal AI. These systems combine satellite data, ground sensors and predictive models to produce a continuous picture of emissions and leaks. As a result, companies can respond faster to incidents and quantify their environmental performance for stakeholders.

AI applications in energy can reduce CO2 emissions by around 10% through optimization and reduced waste energy CO2 reduction ~10%. Generative AI (genai) tools also accelerate reporting by summarizing sensor feeds and drafting regulatory submissions that engineers can review. This reduces manual reporting time and improves consistency in ESG disclosures.

Environmental monitoring and ESG agents help companies comply with regulations and reassure regulators and investors. For instance, agents can produce a forecast of emissions for a field, then propose operational changes to lower flaring or energy intensity. These recommendations may include setpoint changes, route adjustments or demand shifting at site power systems. That forecast capability helps operations plan interventions and value environmental improvements against production targets.

In addition, ai technology that embeds data processing across sensors, reports and dashboards supports auditability. An environmental dashboard shows real‑time emissions, historical trends and suggested mitigations. This transparency makes it easier for teams to show progress to stakeholders and for boards to monitor performance.

Finally, environmental agents create new opportunities for optimization. They let companies balance production and emissions objectives, and thus transform oil and gas operations into more efficient, lower‑emission enterprises. By adding specialized ai agents that focus on monitoring and control, firms can reduce downtime, improve ESG metrics and demonstrate operational excellence.

use cases, companies using advanced ai and scaling ai — specialised ai, autonomous and ai‑first strategies

There are many concrete use cases across the industry. For example, Chevron uses AI to ensure reliable energy supply to data centers, showing how energy companies tie AI to both reliability and sustainability goals Chevron AI for data centers. Other deployments include remote operations, supply chain optimization, demand forecasting and autonomous inspection with drones and robots.

Specialized AI and advanced AI deployments include autonomous agents that inspect flare stacks, chatbots that triage vendor requests, and specialized ai agents that parse geological reports. Traditional AI approaches coexist with agentic ai that can act across systems. Companies using advanced AI often adopt an ai-first strategy that focuses on modular models, observability and governance.

Workforce changes follow. While LinkedIn research suggests some roles will be affected, field personnel typically remain essential for hands‑on tasks. Meanwhile, data analysts and model stewards take on higher‑value responsibilities. Governance and safety guardrails are essential as autonomous ai agents take on greater responsibility.

To scale, pilots must have measurable KPIs and clear pathways to production. Use an ai platform that supports model lifecycle, orchestration and integration with ERP and IOT. For operational email flows that interrupt workflows, consider targeted automation for shared inboxes; virtualworkforce.ai provides a template for reducing handling time and improving traceability across logistics and operations scale logistics operations with AI agents.

Finally, companies must set data standards and safety rules before they expand. That includes defining escalation logic, audit logs and performance thresholds. By doing so, oil and gas companies can scale AI from pilots to enterprise AI deployments and reshape the future of oil and gas while managing risk.

FAQ

What is an AI agent and how does it differ from traditional automation?

An AI agent senses data, makes decisions and acts, often using machine learning and analytics. Traditional automation follows fixed rules, while an AI agent can adapt to new patterns and learn from data over time.

How do agentic AI agents help in upstream oil and gas?

Agentic AI agents analyze seismic data and well logs to rank prospects and guide drill planning. They reduce uncertainty and help teams identify promising drilling targets with higher confidence.

Can AI reduce maintenance costs for oil and gas operations?

Yes. Predictive maintenance agents forecast failures so teams can schedule repairs proactively, which reduces downtime and maintenance spend. Industry examples show maintenance cost reductions around 15–20% case studies.

What role do orchestration layers play in workflow automation?

Orchestration layers connect models, data and business rules so that multi‑step workflows run reliably and audibly. This streamlines coordination across teams and creates a consistent audit trail.

How can AI assist environmental monitoring and ESG reporting?

AI agents detect leaks, estimate emissions and produce forecasts that operations can act on. These tools also help prepare ESG reports faster and with standardized outputs, supporting regulatory compliance.

Are autonomous agents safe to deploy in critical oil and gas systems?

They can be, when paired with strict governance, human escalation points and thorough testing. Start in low‑risk workflows, validate performance, then expand under controlled conditions.

Which companies are actively using AI in oil and gas?

Major energy companies and independents deploy AI across exploration, production and logistics. For example, Chevron has publicized AI for energy reliability at data centers Chevron example.

How should organizations begin an AI journey in operations?

Begin with measurable pilot projects on high‑value processes, then integrate successes into an ai platform that supports orchestration and governance. Also, involve domain experts early to ensure models reflect real operational constraints.

Can AI help with the large email volumes that slow operations?

Yes. AI agents that automate the full email lifecycle can reduce handling time and improve consistency. For logistics and operations, targeted email automation reduces triage and preserves context; see an example of virtualworkforce.ai’s approach to automating operational correspondence automated logistics correspondence.

What is the future of AI in oil and gas?

The future of oil and gas will include wider use of agentic systems, enterprise AI platforms and integrated environmental monitoring. These tools will help companies optimize production, reduce downtime and meet ESG expectations while reshaping operational models.

Drowning in emails?

Here’s your way out

Save hours every day as AI Agents label and draft emails directly in Outlook or Gmail, giving your team more time to focus on high-value work.