How AI and the automotive supply chain combine: market facts and impact

The convergence of AI and the automotive supply chain is measurable and accelerating. The AI in automotive market was valued at roughly USD 4.8 billion in 2024 and projects very large growth, with a reported CAGR around 42.8% to 2034 source. At the same time, a McKinsey brief notes that generative AI can shorten parts-development timelines by 10–20% and drive outsized returns, with cited ROI figures reaching about 350% in some studies source. Those numbers matter when the average manufacturer must coordinate hundreds of suppliers, manage stock levels across plants and avoid downtime that costs thousands per hour on a production line.

To put this in practical terms: today’s automotive companies juggle parts availability, delivery times and quality checks from multiple geographies. AI adds data-driven visibility and new capability to identify where a delay will become a stoppage. It helps teams predict shortages and to optimize reorder timing so stock levels hold only what’s needed. Manufacturers that use AI find they can reduce engineering cycle time, lower inventory holding and react faster to supplier disruption.

These trends are already visible across the automotive industry and among industry leaders. For example, dealerships and service networks are reporting faster issue resolution because upstream processes are more predictable; a CDK survey found that many dealerships see positive operational impact from AI tools source. Moreover, the IBM view is that the auto sector is seeing revenue boosts attributed to AI investments source. That combination of shorter development time, financial uplift and improved resiliency is why strategic teams prioritize pilots now.

Chart suggestion: a short chart showing market size (2024 USD 4.8bn), CAGR (42.8%) and impact metrics (10–20% development time reduction; ~350% ROI) gives a compact visual of why the approach matters.

What an assistant and an AI assistant do in the supply chain

An assistant in a logistics team typically answers queries, escalates issues and tracks status. By contrast, an AI assistant fuses real-time data with business rules to automate routine work and propose actions. Where a traditional dashboard just displays numbers, an AI system will analyze those numbers, identify exceptions and either route work or execute a change. The difference is that one tool informs a manager while the other can act to reduce friction automatically.

Concrete tasks include automating status queries, drafting and sending shipment notes, scheduling order changes, and flagging parts that risk causing a stoppage. A virtual assistant provides structured replies from unstructured emails and links them back into ERP and WMS records. For teams that process many inbound notes, automating message triage reduces email handling time and avoids lost context. Our own work at virtualworkforce.ai shows how agents label intent, route queries and draft replies grounded in operational systems, so planners spend time on decisions rather than manual lookup.

Example interaction: a planner asks the system in natural language for the ETA of a critical part. The AI agent queries the carrier telematics and the supplier portal, finds a late leg, recalculates arrival and then offers two actions: route an express carrier or reallocate from a nearby plant. The planner approves one option with a single click and the agent creates the purchase-order change and the shipment note. That flow shows how a bot can reduce wait times, keep part numbers visible and maintain parts availability without lengthy calls or emails.

Drowning in emails?

Here’s your way out

Save hours every day as AI Agents label and draft emails directly in Outlook or Gmail, giving your team more time to focus on high-value work.

Use cases: predict delay, streamline inventory and help carriers with ai-powered routing

AI brings a set of clear use cases that map to measurable outcomes. Below are mission-critical use cases and the one-sentence outcomes they deliver.

- Predictive parts management — predict which part numbers will run low and trigger just-in-time replenishment to cut inventory and avoid shortage.

- Delay prediction — analyze carrier telematics and supplier KPIs to predict a delay and reduce downtime by proactive action.

- Dynamic re-routing for carriers — ai-powered routing suggests alternative legs to optimize delivery times and lower transport costs.

- Automated purchase orders — the system auto-generates POs when thresholds are met, freeing planners from repetitive tasks.

- Real-time visibility dashboards — combine telematics, ERP and factory sensors to provide visibility across the real supply chain.

- Quality and recall alerting — surface early quality signals so teams can contain issues before a wider recall.

Here is a short example: a predictive model flags a high-risk part from a particular supplier. The assistant sends a query to the supplier, flags carrier ETA variance and then triggers an expedited shipment while reallocating stock across plants. That single flow can cut expected downtime and preserve customer satisfaction at the dealership level.

These use cases show why companies choose to use ai and why they often start with one lane, then scale. For teams focused on logistics communication, solutions that automate the full email lifecycle tie directly into these scenarios; see a practical example of automated email drafting for logistics that reduces manual work and speeds responses automated email drafting for logistics. When you use AI in these ways, you both optimize operations and free planners to focus on higher-value decisions.

AI-powered insight to connect domain data and transform operations

Transforming operations depends on the ability to connect domain data from multiple layers: suppliers, carriers, factory sensors, ERP, telematics and dealer feedback. An AI layer sits above these feeds to uncover root causes, to identify patterns and to suggest specific actions. The result is faster decision-making and measurable KPI lift across metrics like delivery times and stock levels.

How insight works: the system ingests streaming telemetry, supplier scorecards and market data, then runs anomaly detection and correlation. When the model finds a signal — for example rising transit time on a lane plus a supplier quality dip — the AI assistant can propose an action plan for the planner. Actions can be automatic, such as a temporary reroute, or advisory, such as a recommendation to increase buffer stock for a specific part.

Those suggestions help managers move from firefighting to planned contingency. The shift produces measurable results: fewer production stops, lower inventory management costs and improved resiliency. You can also use the same AI to analyze aggregated feedback from dealerships and service centres to improve spare parts distribution and customer experience. By connecting data, the system helps teams uncover areas for improvement that were previously hidden in messages and spreadsheets.

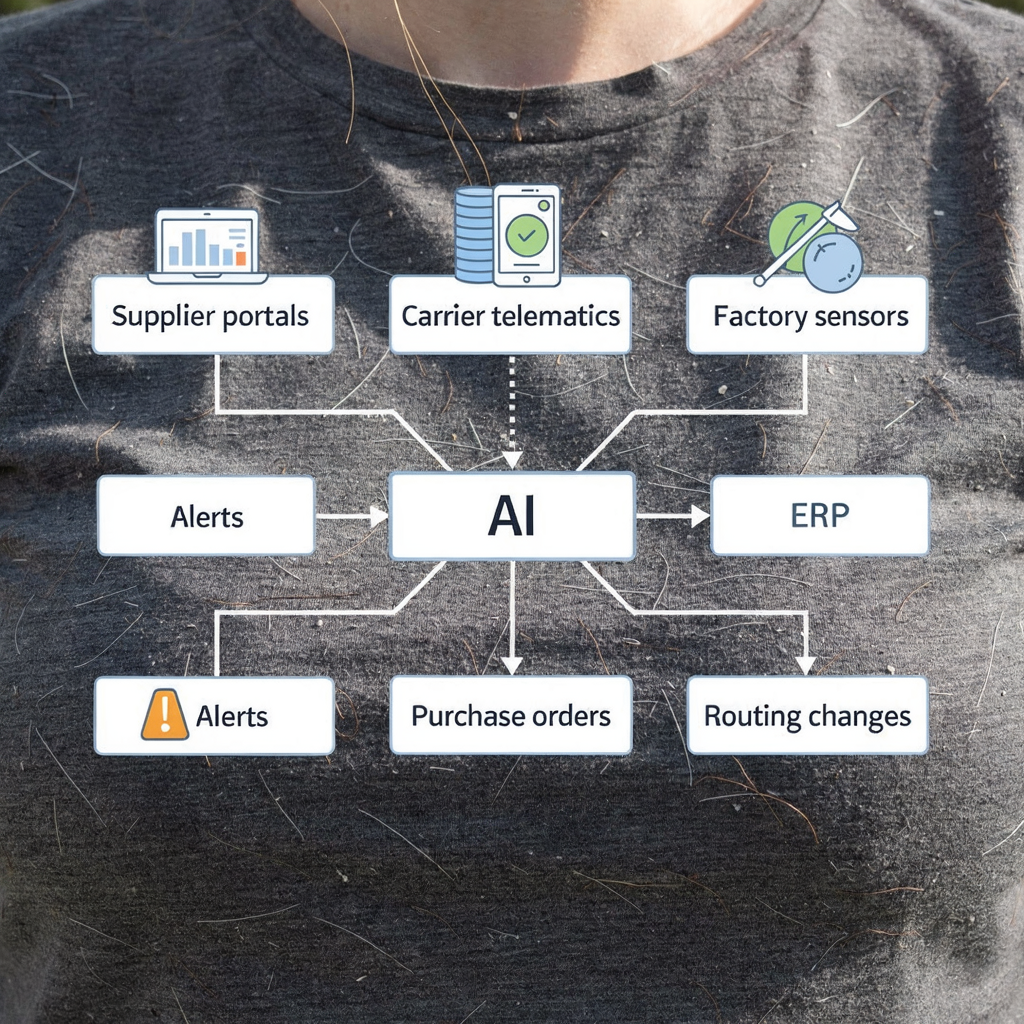

Simple diagram idea: suppliers, carriers, ERP, sensors and dealer feedback → AI layer → actions and alerts for planners and carriers. For teams who want to automate logistics emails and keep threads grounded in ERP and WMS, our platform links operational systems directly to replies so context stays with the decision ERP email automation for logistics.

Drowning in emails?

Here’s your way out

Save hours every day as AI Agents label and draft emails directly in Outlook or Gmail, giving your team more time to focus on high-value work.

Automotive domain risks and how AI predicts disruption

The automotive supply landscape carries several risks: multi-supplier complexity, late carriers, parts quality problems, cyber threats and poor data integration. AI predicts disruption by fusing signals across the domain. For instance, blending telematics with supplier KPIs and public weather or traffic feeds creates a stronger early-warning than any single feed alone.

When the model forecasts a likely delay or a potential quality issue, it can proactively recommend mitigation steps. Examples include automated supplier re-prioritisation, a suggestion to increase a local buffer of spare parts, or selection of an alternate carrier under contract. These steps reduce shortage risk and preserve production flow. When a recall risk emerges, early detection narrows the scope and cost of containment.

Governance matters. Teams must secure data access, validate models and place human checkpoints for high-impact actions. Integrate AI with clear role definitions: a data owner manages feeds, a domain expert reviews suggested actions and a carrier liaison executes transport changes. This mix keeps control with planners while allowing the system to act where safe to do so.

Operational teams that integrate ai can see reductions in wait times and fewer manual escalations. That said, not every use case should be automatic; AI-driven recommendations must be validated and auditable. For an operational pattern that spans multiple emails and documents, automation that routes or drafts responses dramatically reduces triage time; see how automated logistics correspondence can help teams scale without hiring automated logistics correspondence.

How to implement an AI assistant to connect teams, streamline work and empower planners

Start with clear, limited pilots. Define two use cases, secure data feeds from ERP and a carrier telematics provider, then pilot on 1–2 parts or lanes. Measure simple KPIs: delay reduction, inventory days and email handling time. Early wins build momentum and support scale-up.

Organisation matters. Assign a data owner, a domain expert for parts and a carrier liaison. Train planners on a staged change plan so they can approve recommended actions and trust the agent. Set iteration cadences: weekly for model tuning, monthly for KPI review and quarterly for broader rollout. Expect to see ROI from reduced manual work and faster decision-making.

Practical checklist — three immediate first steps:

- Choose a pilot lane and define success metrics (delay, downtime, inventory).

- Connect core feeds: ERP, carrier telematics and supplier portals; secure governance for those feeds.

- Deploy an AI agent to triage messages and propose actions, then measure results and iterate.

When you integrate ai, the organisation moves from reactive firefighting to proactive planning. Teams that adopt this approach empower planners, improve resiliency and deliver measurable results across the business. For logistics teams focused on scaling without hiring, guidance on scaling operations with AI agents shows practical steps and outcomes how to scale logistics operations with AI agents.

FAQ

What is an AI assistant in the automotive supply chain?

An AI assistant is a system that analyzes data from suppliers, carriers and factory systems to automate routine work and propose or take actions. It reduces email triage and speeds decision-making by grounding responses in ERP and WMS data.

How quickly can AI reduce parts development timelines?

Reports show generative approaches can shorten development timelines by around 10–20% in some cases. That reduction comes from faster design iteration and better integration between suppliers and engineering teams source.

Can AI predict supplier delays?

Yes. By fusing telematics, supplier KPIs and external feeds, AI models can forecast a likely delay and recommend actions to avoid downtime. These predictions help prevent costly production stops.

How does AI help with inventory management?

AI forecasts demand and suggests reorder points to reduce excess stock while preserving parts availability. This predictive approach supports just-in-time replenishment and lowers inventory holding costs.

Is data security a concern when implementing AI?

Data security is critical. Teams should formalise data access, use role-based controls and validate any model before automation. Governance ensures actions remain auditable and safe.

What metrics should a pilot measure?

Start with delay reduction, downtime avoided, inventory days and email handling time. These indicators show if the project is delivering measurable value.

How do AI agents handle emails in logistics?

AI agents label intent, draft replies grounded in ERP and route or resolve messages automatically. This reduces manual lookup and speeds responses across operations; see an example of logistics email drafting in practice here.

Will AI replace planners?

No. AI helps planners by automating repetitive tasks and surfacing recommendations so human experts handle strategic decisions. The system empowers managers and reduces low-value work.

What are common implementation challenges?

Common challenges include integrating diverse feeds, ensuring data quality and winning user trust. Pilots with clear governance and quick wins help overcome these barriers.

How does AI improve customer experience at dealerships?

By improving parts availability and reducing delivery times, AI helps dealerships meet customer expectations and reduces wait times for repairs. That flow improves overall customer satisfaction and supports service revenue.

Drowning in emails?

Here’s your way out

Save hours every day as AI Agents label and draft emails directly in Outlook or Gmail, giving your team more time to focus on high-value work.