How AI is reshaping maritime operations and freight

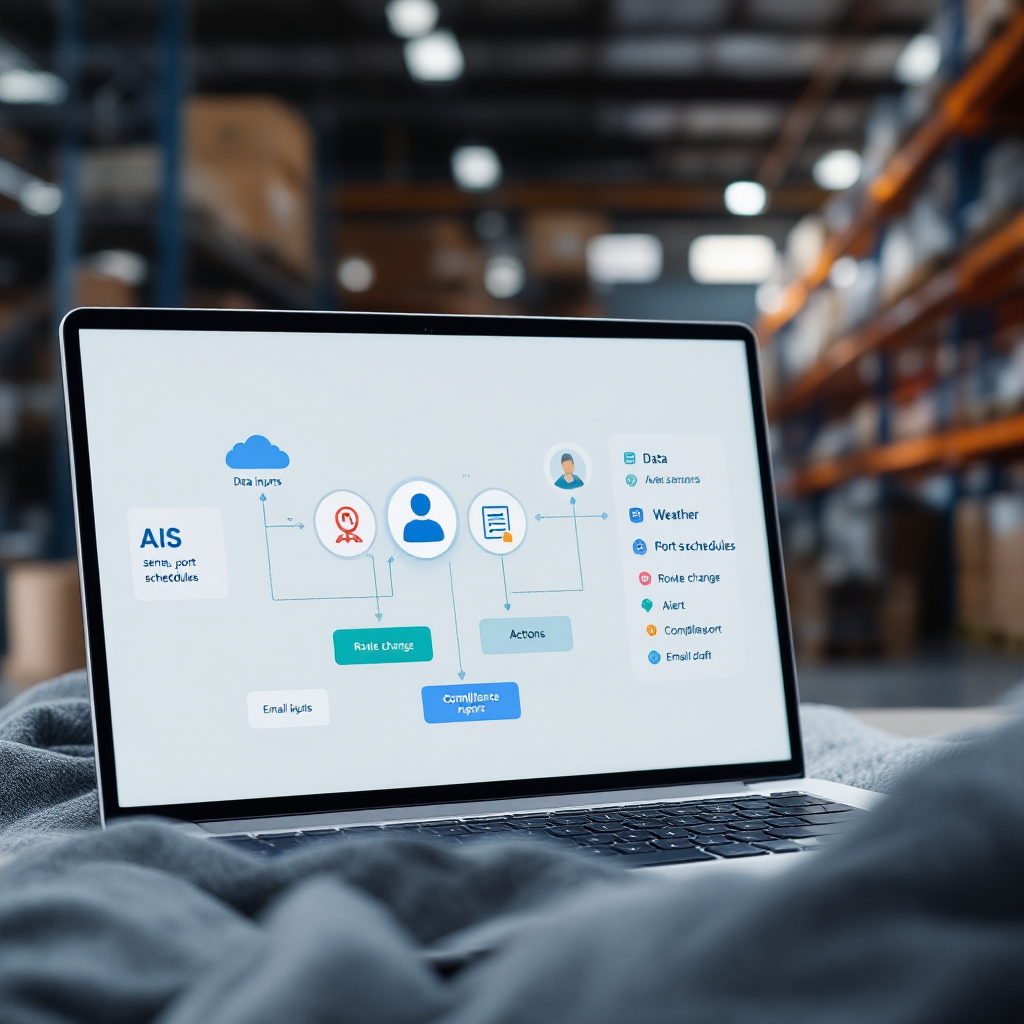

AI assistants now act as real-time copilots for maritime teams. They analyse AIS feeds, weather forecasts, onboard sensors and port schedules to deliver instant responses and actionable alerts. In short, an AI assistant helps logistics teams reduce manual steps, improve ETA accuracy and streamline email-heavy workflows. For clarity, ai-powered tools in this space include digital twins, predictive route planners and communication agents that draft context-aware replies inside Outlook or Gmail.

Market momentum is clear. Since 2018 there has been an 11% rise in projects and organisations reporting AI use in maritime operations, which shows growing adoption across the maritime sector (Thetius). At the same time, a 2024 MIT supply chain study found that many organisations use less than 25% of their available data for AI projects, which means large upside for teams that adopt ai systems (DocShipper). Industry reports estimate targeted AI use can cut logistics costs by about 15% for some operations, while shipping companies plan significant investment in the next 12–24 months (Relevant Software).

Dr. Elena Martinez summarised this shift well: “AI is not just automating tasks; it is augmenting human decision-making in marine logistics by providing predictive insights that were previously unattainable.” That quote emphasises how artificial intelligence enhances safety and decision support across vessel operations and port planning (MDPI). For logistics teams, the immediate value appears in reduced email handling time, fewer missed ETA updates and faster exception handling. For example, virtualworkforce.ai offers no-code AI email agents that ground replies in ERP/TMS/TOS/WMS and cut handling time from roughly 4.5 minutes to about 1.5 minutes per email, which helps both ship crews and ashore teams respond faster and with more accuracy.

Finally, companies that adopt an ai platform early gain operational efficiency and better situational awareness. Consequently, they reduce human error and lower fuel costs. Next, we will examine how these systems use vessel telemetry and predictive models to optimise routes and fuel consumption.

Using AI-powered systems for up-to-date vessel telemetry and predictive navigation

Real-time vessel telemetry feeds power predictive models that help captains and fleet managers make faster, safer choices. Telemetry includes VDR recordings, AIS positions, ECDIS overlays and a range of onboard sensors for engine performance and fuel burn. These inputs feed ai models that forecast ETA, fuel consumption and weather-related delay risk. For instance, a predictive model can use sea currents and wind forecasts to recommend a small course change that reduces fuel consumption and shortens transit time.

Operational teams expect low latency from these systems. Typically, sensor feeds update every few seconds to minutes, and model outputs refresh in less than a minute for critical alerts. Accuracy varies by model type: fuel-consumption prediction models often achieve tight error bands when trained on historical engine and hull data, while weather-routing outputs use probabilistic ensembles to balance safety and efficiency. Predictive analytics and predictive maintenance combine to reduce unexpected downtime and to prolong engine life.

Consider a short example. A vessel reports higher-than-expected fuel consumption for its current speed profile. The AI platform analyses current, wind and traffic, then recommends a 0.3 knot speed reduction and a slight course adjustment to avoid a head sea. The crew accepts the recommendation, fuel consumption drops, and arrival remains on-time. This decision sequence delivers actionable outcomes and improves fuel efficiency while maintaining safety protocols.

For on-shore teams, dashboards summarise ETA, fuel burn forecast and suggested course changes in one place. Those views support both tactical decisions and longer-term voyage planning. To learn more about automated communication that ties into these systems, see how an ai-powered freight communication agent drafts replies and logs activity into TMS and ERP systems at virtualworkforce.ai AI for freight forwarder communication.

Drowning in emails?

Here’s your way out

Save hours every day as AI Agents label and draft emails directly in Outlook or Gmail, giving your team more time to focus on high-value work.

AI for fleet management: optimisation, fuel efficiency and tanker operations

AI at fleet scale coordinates schedules, bunkering plans and voyage windows to improve utilisation. Fleet managers use optimisation engines to set speed profiles, schedule slow steaming where feasible and to reduce berth waiting through predictive slotting. These tools support KPIs such as fuel per nautical mile and CO2 per TEU or tonne. Fleet-level software can also recommend which vessel to assign to a voyage to balance fuel costs and utilisation.

Tanker operations add cargo constraints like vapour management and hazardous handling that ai models can encode as hard rules. For a tanker voyage, the optimisation engine must balance safety protocols, cargo compatibility and port restrictions while minimising transit time and fuel consumption. In practice, an AI-driven plan might suggest a sequence of port calls and precise bunkering locations, while ensuring vapour recovery requirements and international maritime regulations remain satisfied.

Fleet optimisation also reduces idle time and unnecessary repositioning. For example, a fleet optimisation pilot can lower empty-leg movements and thus cut fuel costs and CO2 emissions. Fleet managers receive a decision-ready dashboard that highlights recommended speed profiles and bunkering windows. In addition, those dashboards can feed compliance reporting and audit trails, which helps shipowners and charterers. The integrated approach ties operational efficiency with environmental goals and continuous improvement.

For logistics teams who want to streamline email responses and reduce manual checks linked to fleet schedules, our logistics assistant features automate repetitive correspondence and keep schedules current across email and TMS systems; see the virtual assistant for logistics page for setup and ROI details virtual assistant for logistics.

Automation and artificial intelligence for compliance reporting and risk management in the maritime industry

Automation reduces administrative overhead and improves audit readiness. AI assistants can auto-generate compliance reporting for frameworks like EEXI, CII and MRV by ingesting vessel telemetry and voyage logs, then mapping metrics to regulatory templates. This saves time, reduces errors and accelerates audits. For example, an automated compliance reporting pipeline can pull engine hours, fuel consumption and load data, then produce compliant outputs and an audit record.

Security and data standardisation remain the main barriers. To secure data flows, teams should use encryption in transit and at rest, strict access controls, role-based permissions and detailed audit logs. Additionally, establishing canonical data models improves interoperability between terminal operating systems and port community systems. Aligning these feeds with international maritime regulations prevents rework and reduces compliance risk.

Regulatory watch is essential. New rules and regional requirements arrive frequently, so firms must keep their ai platform updated. In practice, AI systems flag deviations and send an alert to compliance officers with supporting evidence, which speeds remediation. Typical time savings vary, but teams often report 30–60% reductions in reporting time for routine compliance tasks.

For companies focused on reducing email and document friction during compliance cycles, automated logistics correspondence tools link email threads with evidence and generate consistent replies. Virtualworkforce.ai provides no-code connectors that cite ERP and TOS records, which helps teams produce accurate responses and maintain audit trails automated logistics correspondence.

Drowning in emails?

Here’s your way out

Save hours every day as AI Agents label and draft emails directly in Outlook or Gmail, giving your team more time to focus on high-value work.

End-to-end freight and shipment visibility with AI-powered maritime solutions for logistics operations

End-to-end visibility links ports, carriers and supply-chain partners so teams can re-route shipments before delays become costly. AI platforms integrate with port community systems, terminal operating systems and forwarder platforms to predict congestion and to automate documentation. When a port delay is predicted, the system can propose alternate berths or suggest re-routing the shipment to another origin or destination, which reduces demurrage and detention risk.

Integration points include terminal APIs, carrier EDI feeds and customs documentation flows. An AI-powered maritime hub consolidates that data and provides a timeline view of the shipment lifecycle. The result: improved on-time performance and fewer manual emails. For example, a logistics assistant can draft and send a reroute notification to the consignee and then log the change in the TMS, all while maintaining email thread context and citing the source data.

Who needs access? Operations, chartering and commercial teams all benefit from shared visibility. Ship crews benefit indirectly through clearer instructions and reduced last-minute changes. Fleet managers and shipowners gain a single source of truth for origin and destination planning. For practical guidance on automating customs and shipment emails, see the AI for customs documentation emails resource which explains common integrations and templates AI for customs documentation emails.

Finally, end-to-end visibility supports instant answers to partner questions and instant responses to customers. When the platform predicts a delay, it pushes an actionable alert to the right users and suggests next steps. This process reduces manual checks, cuts fuel costs from inefficient diversions and helps to improve decision-making across the whole freight chain.

Deployment roadmap: automation, up-to-date decision support and KPIs for artificial intelligence in maritime logistics

Begin with a focused pilot. Select a single route or vessel class and define measurable KPIs such as fuel consumption per nm, on-time arrival rate and reporting time. Early wins often appear within 3–12 months and include reduced fuel costs, fewer late arrivals and faster compliance reporting. Use an iterative approach: pilot, measure, refine, then scale.

Tech readiness matters. Check data quality, confirm API access to AIS and ECDIS layers, and decide between cloud vs edge compute for latency-sensitive tasks. Include predictive maintenance and analytics in your scope to reduce downtime and to extend component life. For email-heavy teams, consider no-code AI email agents that integrate with ERP/TMS/TOS/WMS to automate daily tasks and to provide context-aware replies, which reduces human error and speeds correspondence. See how to scale logistics operations without hiring for examples and playbooks how to scale logistics operations without hiring.

Change management must include onboard training for ship crews and ashore users, plus clear escalation paths. Security checks should cover encryption, role-based access and supplier SLAs. Use a KPI dashboard template to track progress and to feed continuous improvement cycles. Decision criteria for scaling include consistent ROI on the pilot, stable data feeds and crew acceptance. Finally, maintain vendor SLAs for uptime and ensure alignment with international maritime regulations to avoid compliance gaps.

As a practical next step, form a small cross-functional team of maritime professionals, IT and operations to run a 6–12 month rollout timeline. Track metrics weekly and refine models as more data arrives. Over time, the organisation will see better fuel efficiency, reduced fuel consumption and improved operational efficiency as AI-driven practices become standard.

FAQ

What is an AI assistant in marine logistics?

An AI assistant is a software agent that automates routine tasks, analyses vessel telemetry and drafts context-aware messages. It helps teams respond faster to exceptions and supports data-driven decisions across vessel operations and port planning.

How does AI use vessel telemetry to improve ETA accuracy?

AI analyses feeds such as AIS, ECDIS overlays and onboard sensors to model fuel consumption and current vessel performance. The system then produces ETA updates and recommends minor adjustments that can reduce fuel consumption and delays.

Can AI systems generate compliance reporting automatically?

Yes. AI platforms can pull telemetry and voyage logs, map metrics to EEXI, CII and MRV templates and produce audit-ready reports. They also create an audit trail that speeds inspections and reduces manual effort.

Are AI solutions secure enough for shipping companies?

Security depends on architecture and governance. Best practices include encryption, role-based access controls and audit logs. Vendors and shipowners should verify these controls in vendor contracts and during implementation.

How quickly do organisations see ROI from fleet optimisation pilots?

Typical pilots return value in 3–12 months, depending on scope and data quality. Early wins often include reduced fuel costs, fewer idle hours and faster reporting cycles.

What data sources do AI models need for predictive analytics?

Key sources include AIS, VDR, engine sensors, weather forecasts and port schedules. The richer the historical and contextual data, the more accurate the predictions become.

Can AI help reduce human error on board?

Yes. AI-driven alerts and decision support reduce repetitive tasks and help seafarers focus on high-value decisions. Systems also provide instant responses and clear evidence for actions, which reduces mistakes.

How does AI affect tanker operations differently?

Tanker voyages require modelling of cargo-specific constraints such as vapour management and compatibility rules. AI can encode these constraints and produce safer, more efficient voyage plans.

What role do email automation tools play in maritime logistics?

Email automation tools streamline routine correspondence by grounding replies in ERP/TMS/TOS/WMS and email history. This reduces handling time and keeps partners updated with accurate ETA and shipment data.

Where can I learn more about implementing AI for freight communication?

Start with practical resources that explain integration with freight forwarding systems and email workflows. For a focused guide on AI for freight forwarder communication and no-code email agents, see the relevant implementation pages at virtualworkforce.ai AI for freight forwarder communication, virtual assistant for logistics, and automated logistics correspondence.

Drowning in emails?

Here’s your way out

Save hours every day as AI Agents label and draft emails directly in Outlook or Gmail, giving your team more time to focus on high-value work.